My main enjoyment is in the design of a craft project. The next interest is how to make what I have designed.

Almost all of my projects involve the use of CNC (Computer Numeric Control) of machine tools.

I have a shop full of electrical powered machine tools. Both hand operated and CNC operated. Materials can be wood, metals, wax and plastics.

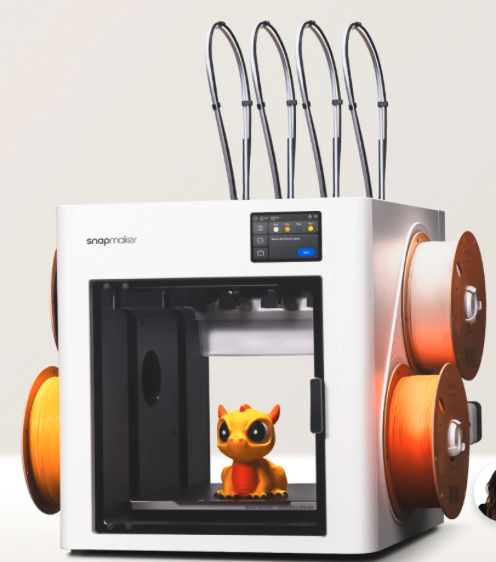

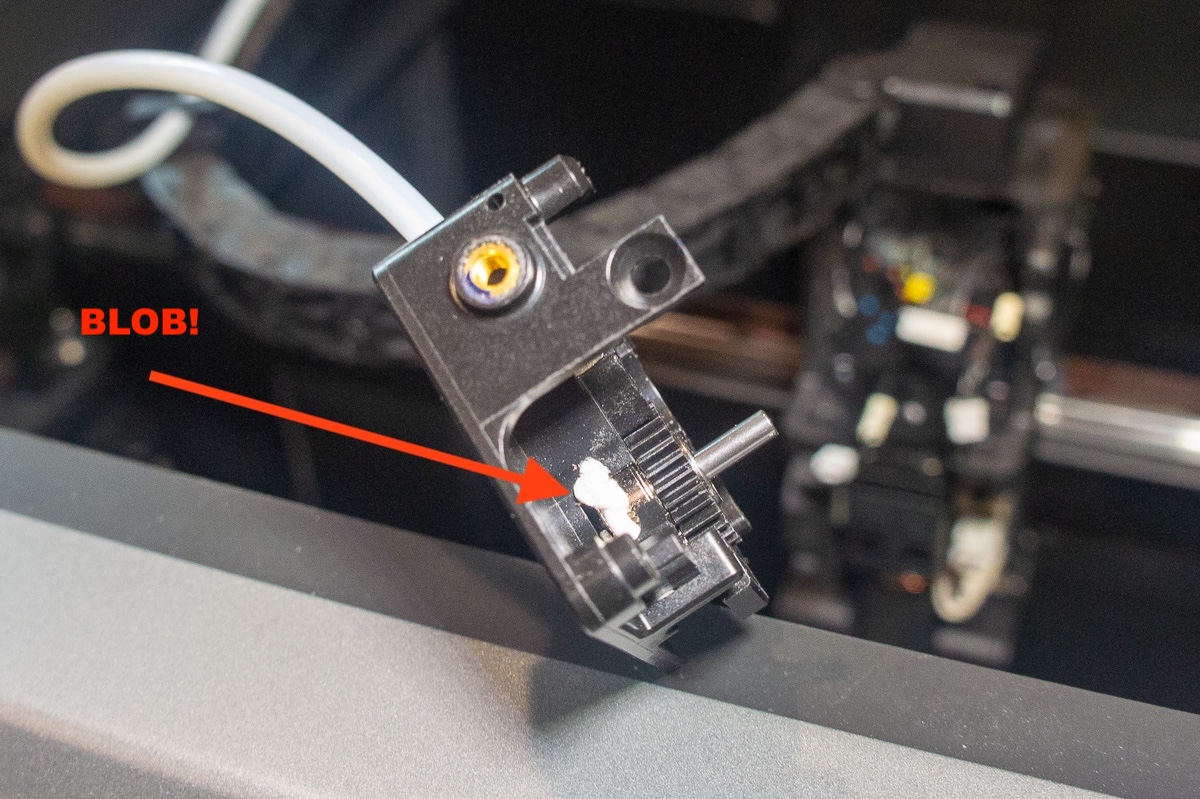

3D Plastic items can be formed using light cured resins and/or FDM extruded filament layered printing. (3D printing).

Wax can be 100% hand shaped with hand held tools. (e.g. – saw, knife, rotary hand burr, files, scrapers.) Or shaped by using a 3 or 4 axis CNC milling process. Wax is then Lost Wax process cast into a metal part.

Raw metal stock is either hand or CNC shaped by lathe turning and 3 or 4 axis milling.

Wood items are formed with conventional hand and power (table and band) sawing. In my shop, wood planing is by hand.

I do not produce super detailed mechanical drawings for any of my hand process made items. A semi-detailed hand drawn sketch with critical dimensions is totally sufficient in a one person craft shop. I know my Idea vision and sometimes like to just work with the small details “on the fly”.

But CNC tools are a totally different environment. They demand absolute total instructional definitions. Some day the machine tool may incorporate the new FAD of AI (Artificial Intelligence) but that day will never be embraced by myself if it takes over the creative process.

II don’t even want the CAD (drawing) process to do my design thinking. Assistance like “draw a chamfer on all 90 degrees edges 1 mm radius ” is OK. But don’t take away basic design thinking.

Again, My main interest is in the designing process. I will not want a computer program to DO all my thinking. Just give me help with specific details when I ask for them.

I will be watching where this AI “thing” may be headed. It’s probably the “future” for some industrial applications. A true “craft-person” will always want to keep the “person” in the creative process.

For me, no walking up to the “replicator” and asking for a three color 200mm tall vase with a handle. Wait 3 minutes (snap, crackle. pop), open door and remove newly designed and created vase. No thank you. <G>